- Description

- Brand

Description

three-paddle polarization controller,connect 1/4 wave plate, half wave plate and 1/4 wave plate in seriescanwill be arbitrarypolarizationThe status is changed to another.any polarizationStatus.firstthe first 1/4 wave plate will be enteredstate to linearpolarizationstatus;Secondly, through the middlehalf wave plate will makelinear polarization staterotation;Finally1/4 wave plate to convert linear stateOtherpolarizationstatus.Therefore, adjust the threeblade(fiber optic reducer) can fully control the output inpolarization states in a wide wavelength range from 300 to 2100 nm.

with quantum production has high stability and can support the usepaddle of Ø27mm ring or Ø56mm ring.

Bare Winding Method:

three-paddle polarizationcontrolleroptical fiber900µmsleevefiber. Winding on a three-paddle polarization controlleroptical fibers,needsconsiderationthe type of fiber required (using wavelength) andlength(polarization controllertotal length, total loop length,and additional working length required for external connections on both sides of the device).

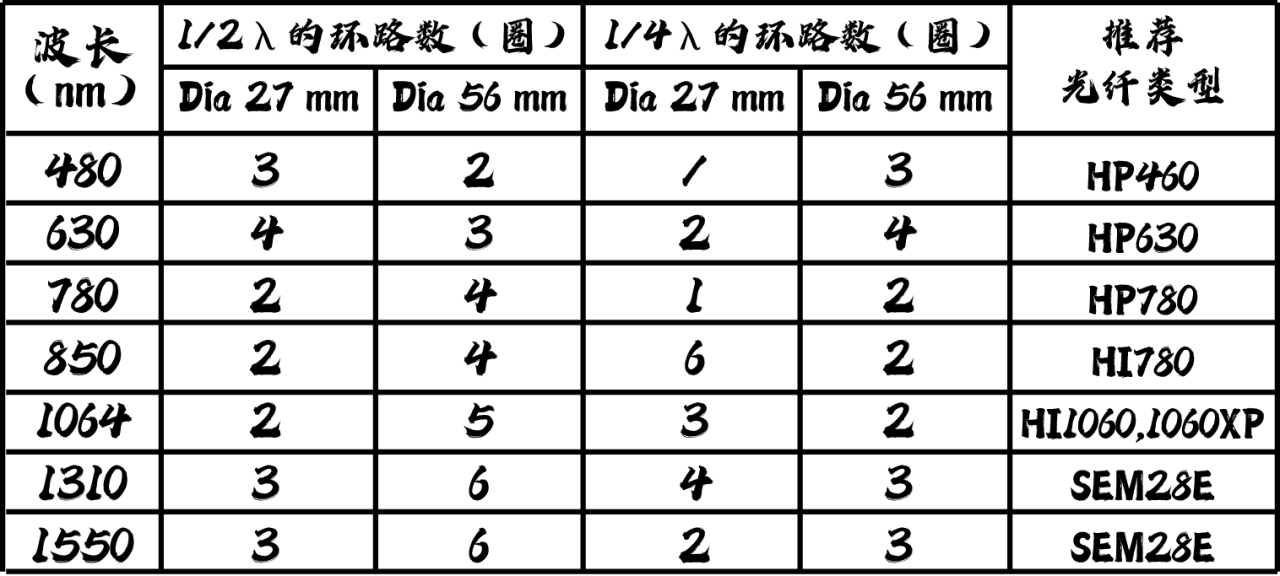

The following table gives1/2and1/4wavelengths under blades of different diameters and the recommended optical fiberstype.

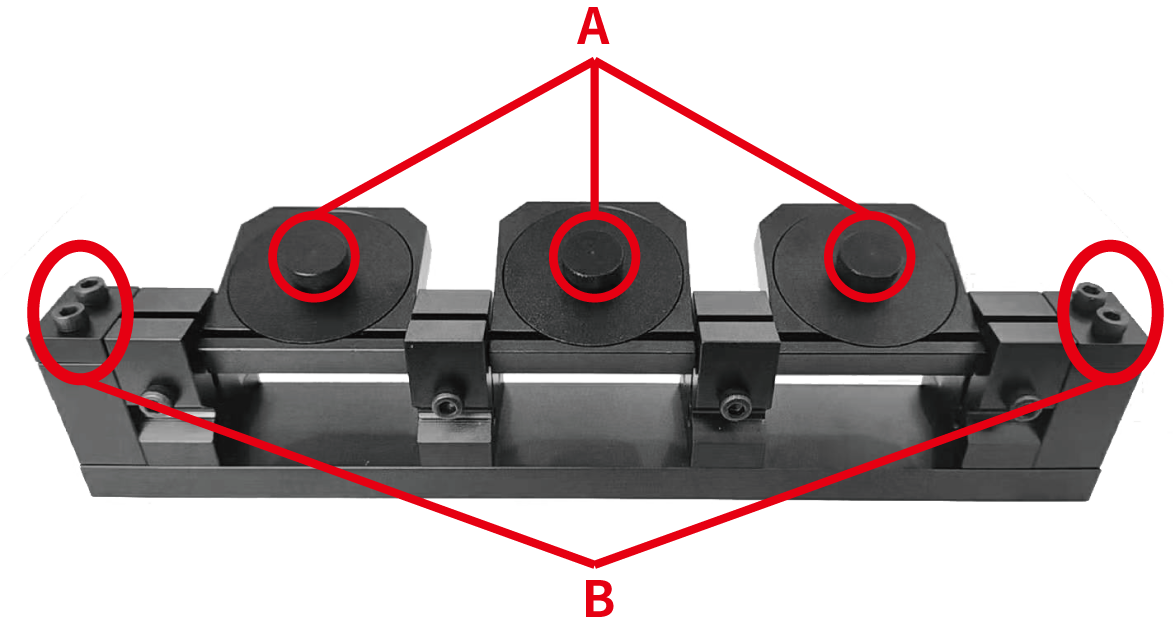

1. Loosen eachblade(A).

2. Two of the fiber polarization controllershexagon sockethead screwcover(B). Removetwothe screws and remove the rectangular cover.

3. Place the lever horizontally with the groove ring facing upward. Groove on Bladeshould be connected with the base bracketBoth endsditchThe slots are aligned.

4. Use the optical fiberplaced in the groove under the cover plate on one side,and continue to lay optical fibers along the trench path, lay the required number of loops on each blade and finally pass through the other end of the controller.optical fiber shouldis always in the ditchthe inside of the slot, but don't pull it too tightly, as this will causeinblades rotate with each otherproduces induced birefringence, thus increasing optical loss.

5. Make sure that the optical fiber is located in each blade.ditchin the slot,before fixing the optical fiber on the next blade,can first put the previous paddleslide valve covergentlytightening, willthe optical fiber is fixed in place.

6. Gently tighten the rectangular cover plates at both ends of the controllerscrew.

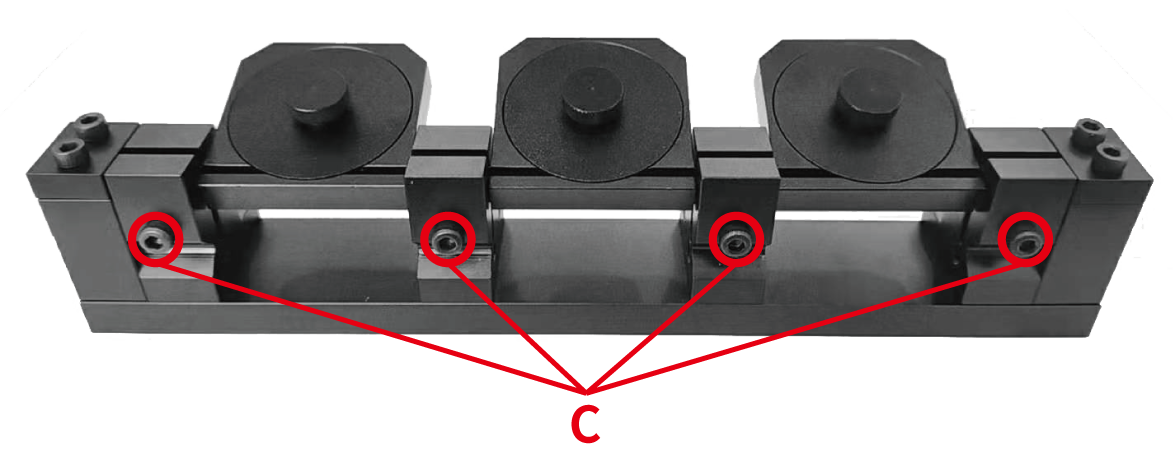

7. Tighten the hexagon socket screw (C)controls the tightness of each blade.

Brand

OEfind

相关产品

Quantum Cryptography Experiment System

$1,000.00

Geiger-mode InGaAs Avalanche Photodiode

$1,000.00

Manual Polarization Controller

$1,000.00